Excellent video on PCB stack-up and other issues:

Notes:

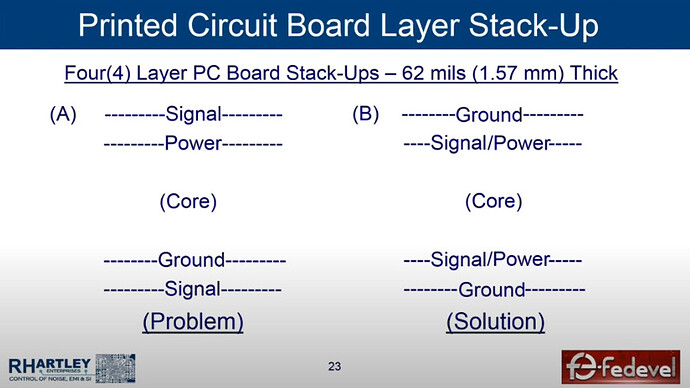

- decoupling caps between power ground planes help if a traces changes from ground reference to power, but this only works up to 200-300MHz. (This would be typical of 4-layer board with signal, gnd, power, signal)

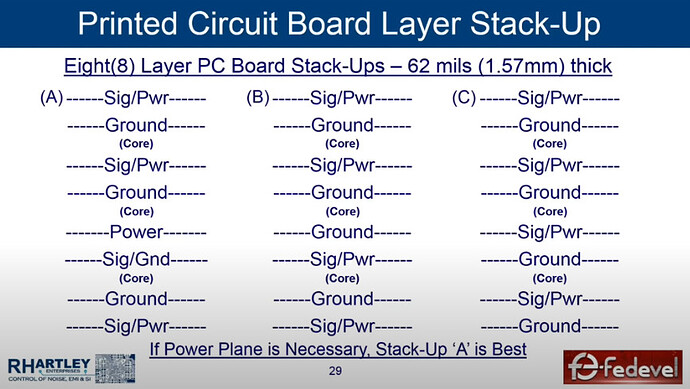

- keep power and ground planes close to each other < 0.2mm (8mil), then the planes look like a capacitor.

- power plane reference should be the same power source that generated the signal

- very small amounts of energy can cause EMI problems, where much higher amounts of energy are required to cause signal integrity problems.

- energy couples by the square of the distance

- to couple planes, place via every 10th wavelength of highest frequency

- inductance between power planes must be low

- its not our job to make things easy, its our job to make them work

- pouring ground on top/bottom layers lowers EMI not because it is a shield, but because it is a reference for signals and power

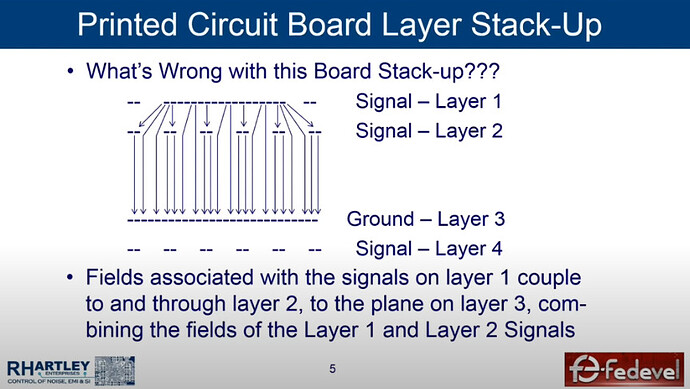

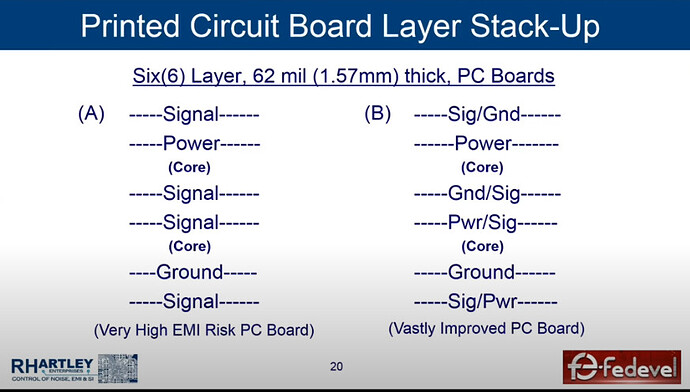

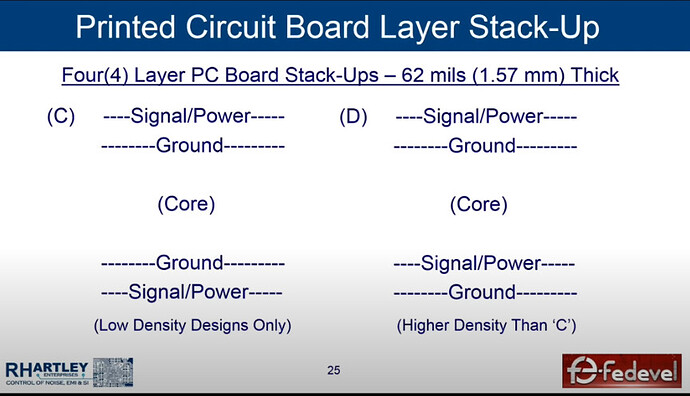

- there is no 4-layer stack-up that is wonderful

- vias have highest inductance of anything in the board stackup

- keep power and ground near surface because power delivery needs low inductance

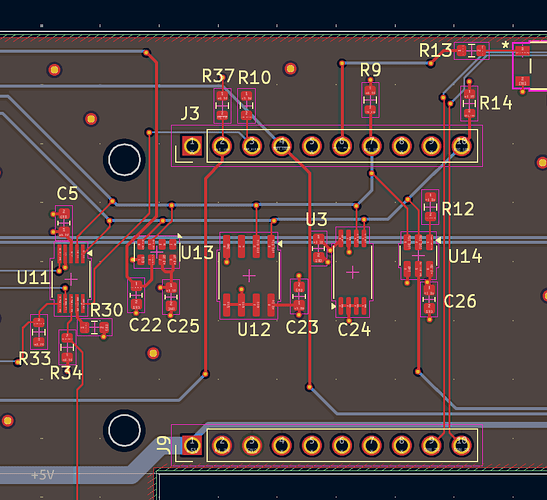

A few screenshots:

In the below board, the change from a classical 4-layer stackup (A) to (B) improve EMI performance because it improved the cap coupling between ground and power.

![[LIVE] How to Achieve Proper Grounding - Rick Hartley - Expert Live Training (US)](https://community.tmpdir.org/uploads/default/original/2X/b/bf7d6b89c31652795e3949624a494318d2f554d3.jpeg)